Originating from the German R&D center team carefully crafted

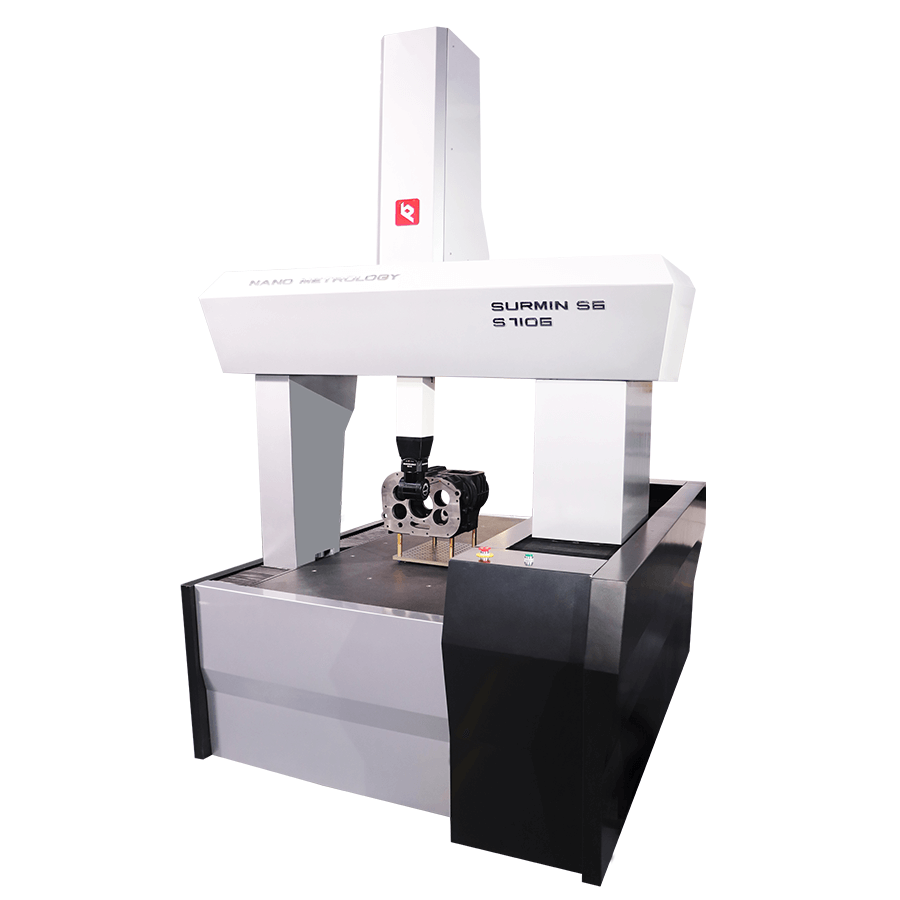

A new generation of ultra-high-precision measurement platform, new industrial appearance and ergonomic design. More than just a CMM.

The all-in-one roughness and contour measuring machine is a precision measuring all-in-one machine independently developed by the company. It has the powerful function of analyzing and measuring the contour shape and surface roughness, and realizes the precise measurement of the three elements of size, shape and roughness.

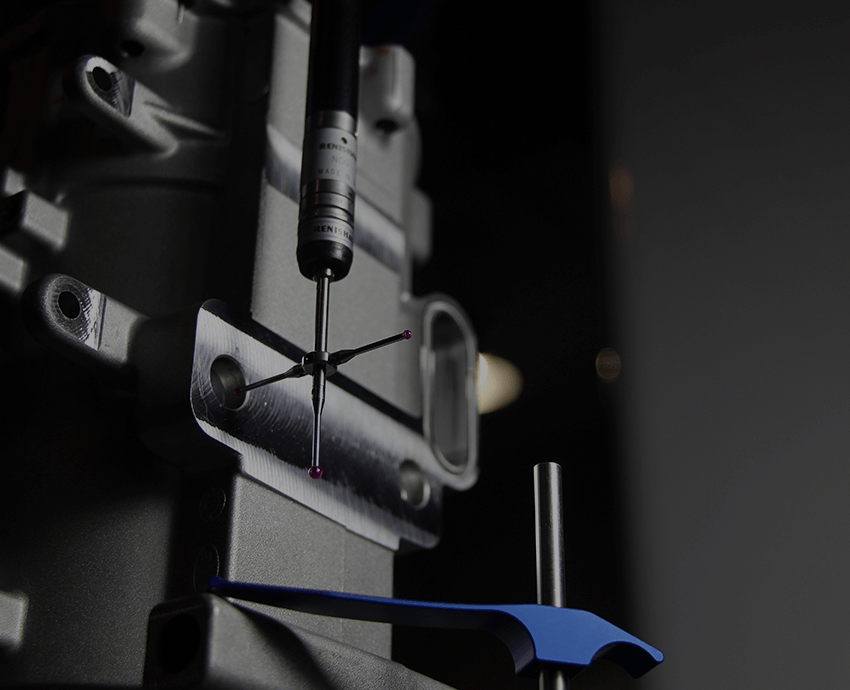

GRADEY type gear measuring center, the basic configuration can measure various shapes of straight, helical, cylindrical gears, and the configuration can measure the full function software of hob, razor, slotting knife, and it also includes turbine, worm, straight helical bevel Spiral bevel gear and other software. It is widely used in the precision inspection of automobiles, machine tools, motor industries, instrumentation, including large-scale shipbuilding, metallurgy, mining, gears in the neutral machinery industry, scientific research departments and factory measurement rooms. 1.high precision motion control machine

2.Natural marble pedestal, imported high precision rolling guide

3.High precision micrometer sensors and high-speed data collection and processing system

SCAN 3D handheld laser 3D scanner uses multi-line laser beams to obtain 3D point clouds on the surface of objects, which is efficient, accurate, flexible, portable, and not limited by the size and shape of objects. The scanner can be easily carried to the industrial site or production workshop, and can perform efficient and accurate scanning according to the size and shape of the scanned object. The operation process is flexible and convenient, and it is suitable for various complex application scenarios.

VARIOUS series products are designed for glass thickness, flatness, and warpage measurement. The whole machine adopts an open structure to provide an open measurement space. The optical measurement system performs non-contact measurement on the surface of the product to be measured.

The SURPASSY series imager adopts the mobile gantry structure of the worktable, and can be equipped with high-precision laser, white light measurement system, and Renishaw side head, which can meet the multi-level measurement needs of customers

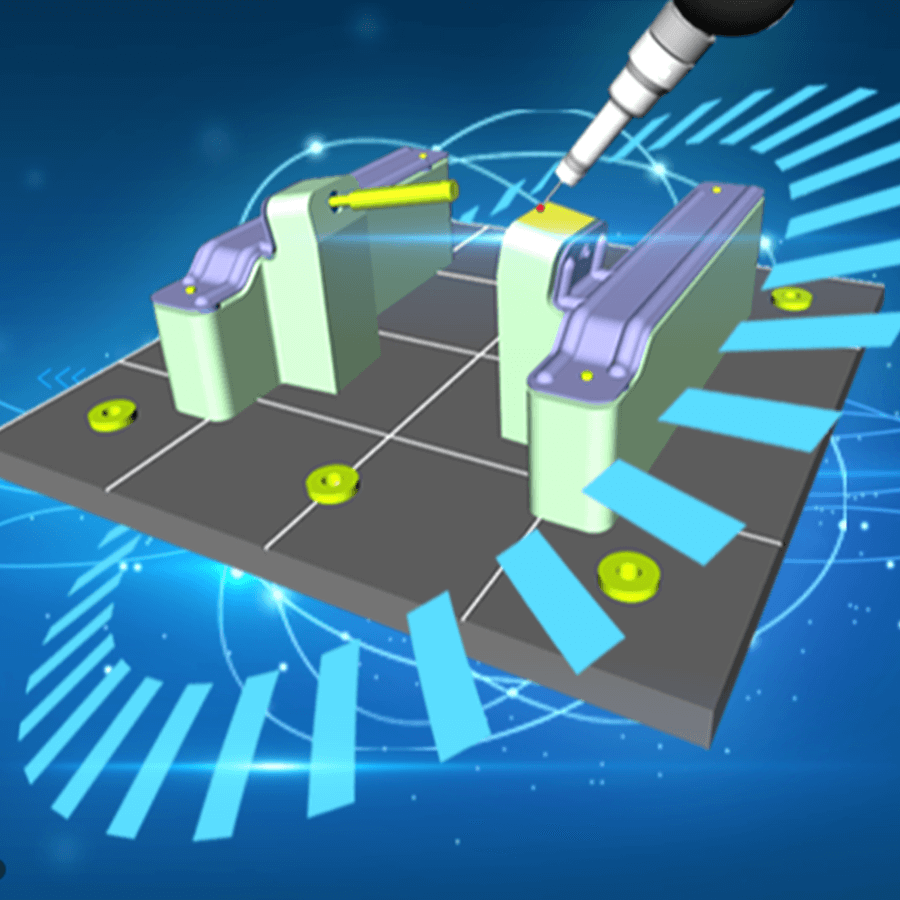

ROYAL series products are stable, efficient and multi-functional, flexible configuration, various measurement configuration requirements and measurement solutions; large measurement space and super heavy load design provide reliable and powerful support for small and medium-sized workpieces.

MICRO series mobile bridge measuring machine is an economical and high-efficiency CMM suitable for small workpiece inspection and reverse engineering.

TITAN series small gantry measuring machine is a high-precision and high-efficiency three-coordinate measuring machine suitable for medium and large workpiece inspection.

Complete the rapid detection of medium and large size workpieces, provide excellent dynamic performance and measurement solutions for overweight workpieces, diverse configurations, meet different workpiece measurement needs, provide scanning and contact solutions, and complete large workpieces with high efficiency and high precision. Check the application.

Used in medium and large weapons, molds, machinery and other industries.